BRINE COOLERS

HTE brine coolers are air coolers named with W_ range, and are meant for the storage, preservation or preparation of fresh goods for small, medium and large cold storage. Brine coolers are using a fluid brine made of water or mixtures of liquids containing ethylene or propylene glycol, HYCOOL or Freezium, unlike the direct expansion cooler unit where the refrigerant cyclically undergoes a change of state htrough expansion.

The HTE brine coolers are designed to cover all applications in refrigeration, such as:

- storage and preparation of fresh products in high and medium temperature

- storage and preparation of the packaged products in high and medium temperature

- ripening and aging of foodstuffs (cheese, meats, fruits)

The cold storage where brine coolers find their application are needing a high stability of temperature and humidity thank to a low temperature difference between brine and air, optimized for the preservation of the food and studied with special care with CFD software simulation of the thermo-hygrometric conditions .

The HTE brine coolers for cold storage refrigeration fully meet the requirements of the application and are designed basing upon a long experience in the industry. They represent the state of the art in air coolers for design quality, attention to details and use of noble materials generously sized for withstand harsh environments without failure or degradation of efficiency.

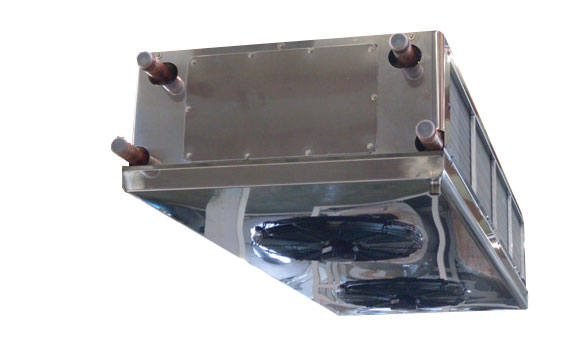

The design standard of HTE brine coolers is unique in the industry, and provides stainless steel casing, copper tubes, oversized aluminum fin surface having low pressure drops, low fouling factor to reduce the amount of defrost cycles, high efficiency fans with external rotor according to Erp 2015 standards.

For cold storage refrigeration with special processes such as cheeses, meats or fruits ripening or in applications like in the tannery industry, where periodic sanitizing of the unit coolers is a must, we have special versions available, with the following constructive features:

- Aluminum fins coated in epoxy resin

- Copper fins

- Tinned copper tubes and copper fins

- Fins treatments as blygold®, heresite®, electrophoresis

- Stainless steel tubes

HTE brine coolers are available with following defrost modes:

- air

- electrical resistance

- water

ADVANTAGES BLAST FREEZER:

- Heat exchanger with high efficiency

- Reduced air dehumidification

- Reduced formation of hoarfrost

- High air throw

- Reduced brine volume

- Low fan power consumption

- Low electric defrost power consumption

Features

| Configurations | |

|---|---|

| Coils | |

| Structure and cover panels | |

| Ventilation |

| Fins | Tubes | Manifolds | Metal sheets | |

| Al - Aluminium | ||||

| Al-P Prepainted aluminium | ||||

| Al-H Hydrofillic aluminium | ||||

| Cu - Copper | ||||

| Ot - Brass | ||||

| Hot bath zinc steel | ||||

| Stainless steel | ||||

| Legenda |

Standard Standard Optional Optional Not available Not available

|

|||

| Protecting surface treatment of the exchanger element | |

|---|---|

| Cover panels |

| Optional | |

|---|---|

| Hydraulics | |

|---|---|

| Electrics, control and regulation | |

| Structural components |

- ECO. Low sound emission AC or EC fans with fan speed controls (wired in to connection box)

- DEFROST. With integrated defrost systems

PRODUCTS

WM_SERIES

[V-Flow]

| V1 | V11 10kW |

V17 200kW |

Enter » |

|---|

|

* Horizontal ceiling construction * Signle fan row * Single coil *Vertical air flow |

Enter » |

[H-Flow]

| H1 | H11 10kW |

H17 200kW |

Enter » |

|---|

|

* Horizontal wall construction * Single fan row * Single coil * Horizontal air flow |

Enter » |

[Dual Flow]

| D1 | D11 10kW |

D17 200kW |

Enter » |

|---|

|

* Horizontal ceiling construction * Single fan row * Double coil * Bi-lateral air flow |

Enter » |

[A-Flow]

| A1 | A11 10kW |

A17 200kW |

Enter » |

|---|

|

* Angular construction * Single fan row * Single coil * Sloping air flow |

Enter » |

[BencHtop]

| B1 | B11 0.5kW |

B17 3kW |

Enter » |

|---|

|

* V-shape constuction * Single fan row * Double coil * Horizontal air flow |

Enter » |

WC_SERIES

[V-Flow]

| V1 | V11 10kW |

V17 200kW |

Enter » |

|---|

|

* Horizontal ceiling construction * Signle fan row * Single coil * Vertical air flow |

Enter » |

[H-Flow]

| H1 | H11 10kW |

H17 200kW |

Enter » |

|---|

|

* Horizontal wall construction * Single fan row * Single coil * Horizontal air flow |

Enter » |

[Dual Flow]

| D1 | D11 10kW |

D17 200kW |

Enter » |

|---|

|

* Horizontal ceiling construction * Single fan row * Double coil * Bi-lateral air flow |

Enter » |

[A-Flow]

| A1 | A11 10kW |

A17 200kW |

Enter » |

|---|

|

* Angular construction * Single fan row * Single coil * Sloping air flow |

Enter » |

WI_SERIES

[V-Flow]

| V1 | V11 10kW |

V17 200kW |

Enter » |

|---|

|

* Horizontal ceiling construction * Signle fan row * Single coil *Vertical air flow |

Enter » |

[H-Flow]

| H1 | H11 10kW |

H17 200kW |

Enter » |

|---|

|

* Horizontal wall construction * Single fan row * Single coil * Horizontal air flow |

Enter » |